Cathode foil for aluminum electrolytic capacitors is a material used in the manufacture of electrolytic capacitors. An electrolytic capacitor is an electronic component that is used to store and release electrical charge and is often used to smooth the voltage or current in an electrical circuit. Aluminum cathode foil for electrolytic capacitors is an important part of an electrolytic capacitor and is usually made from high purity aluminum foil 1235.

Cathode electrolytic capacitor aluminum foil is highly conductive, thin, and lightweight, providing large electrical capacity and stability. The process of manufacturing cathode foil for aluminum electrolytic capacitors involves electrolytic oxidation of the aluminum foil to form an insulating oxide film to increase its capacitive properties and durability. Cathode electrolytic capacitor aluminum foil is widely used in a variety of electronic devices and circuits, such as power supplies, communication equipment, and automotive electronic systems.

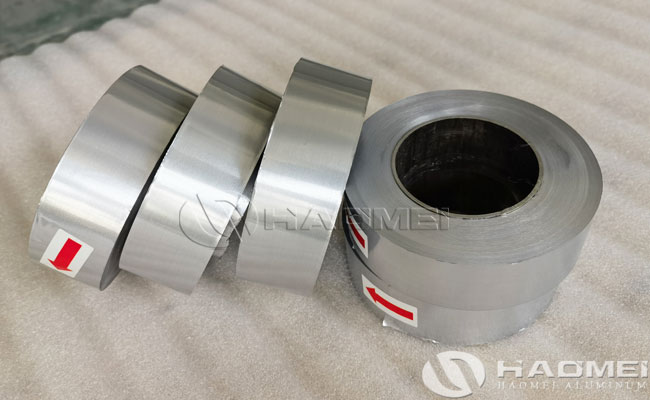

The specification of cathode foil for aluminum electrolytic capacitors:

Aluminum grade: 1235

Temper: O, H18

Thickness: 5-20μm

Width: 3mm-2300mm; can be slit in different widths according to customers’ requirements

O temper:

Thickness 0.006-0.09mm, Tensile strength: 35-100; elongation ≥ 0.5

Thickness 0.010-0.024mm, Tensile strength: 40-100; elongation ≥ 1

H18 temper:

Thickness 0.006-0.200mm, Tensile strength: ≥135

Uses: electronics, cables, lithium batteries and other products.

Packing: export wooden case, wooden pallet

Aluminum foil can be used as the cathode of electrolytic capacitors mainly because it has the following key features:

Excellent conductivity:

Aluminum is a good conductive material, which can provide an efficient electron transfer channel for electrolytic capacitors and ensure stable charge movement between the cathode and anode.

High corrosion resistance:

Aluminum foil easily forms a dense protective layer of aluminum oxide on its surface. This protective layer makes the foil highly corrosion resistant and able to remain stable in the electrolyte for a long period of time, extending the service life of electrolytic capacitors.

Lightweight:

Aluminum is a lightweight material, using aluminum foil as the cathode material of electrolytic capacitors can significantly reduce the weight of the entire capacitor, improving its portability and applicability.

Low production cost:

Aluminum foil is a widely used material with relatively low production cost, and the use of aluminum foil as the cathode material of electrolytic capacitors can reduce the production cost and improve economic efficiency.

In addition, aluminum foil has a certain degree of flexibility and ductility, and can be easily processed into various shapes and sizes to meet the needs of different electrolytic capacitors.

In electrolytic capacitors, the main function of aluminum foil as the cathode is to absorb electrons and transfer them through the electrolyte to the other pole plate (anode). The absorption of electrons at the cathode is achieved by means of a chemical reaction or electrolysis. The high electrical conductivity and corrosion resistance of aluminum foil make it an ideal material for preparing cathodes for electrolytic capacitors.