Hydrophilic aluminum foil for heat exchanger are used in a wide range of applications in heat exchangers, especially in air conditioning systems and refrigeration equipment. The main characteristic of hydrophilic aluminum foil is the good hydrophilicity of the surface, which means that it effectively attracts and disperses moisture, thus improving the efficiency of heat exchange. The surface of hydrophilic aluminum foil is often modified to increase its hydrophilicity through chemical treatments or coating techniques. Common treatments include chemical coatings and electrophoretic coatings. Commonly used coating materials include silicone, acrylic resin, polyurethane, etc. These materials provide good hydrophilicity and corrosion resistance.

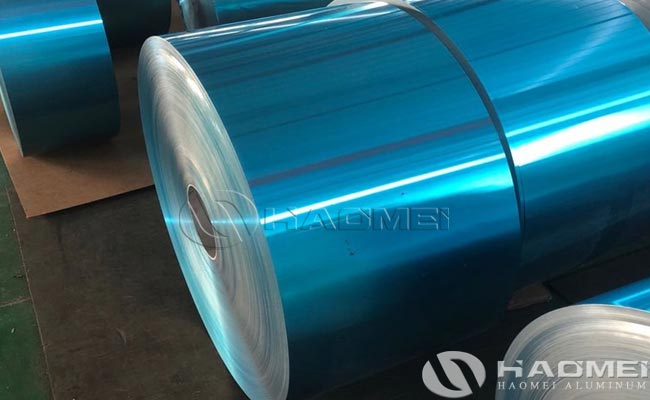

The hydrophilic aluminum foil for heat exchanger usually made from 8011/3003, H22/H24/H26, 8011 aluminum alloy has good formability, corrosion resistance and hydrophilicity, it is the ideal material for manufacturing air-conditioner heat sinks, packaging foils, etc. 3003 aluminum alloy is an aluminum-manganese alloy with high strength and good formability, it is suitable for manufacturing hydrophilic aluminum foil products that require a certain degree of strength. The thickness of hydrophilic aluminum foil is usually between 0.1mm and 0.2mm, depending on the design requirements of the heat exchanger and the heat transfer efficiency.

Characteristics of hydrophilic aluminum foil for heat exchanger are:

– Hydrophilic: The surface of hydrophilic aluminum foil is specially treated to make them hydrophilic, i.e., capable of attracting moisture. This property helps to prevent moisture from forming droplets on the fins and instead distributes them evenly, thus speeding up the evaporation process and improving heat exchange efficiency.

– Corrosion resistance: Hydrophilic aluminum foil are usually treated with an anti-corrosion treatment that allows them to be used for long periods of time in humid environments without rusting or corroding.

– Lightweight: Aluminum foil is inherently lightweight, making it suitable for use in applications with stringent weight requirements.

– Reduced air resistance: Prevents moisture from accumulating on the surface of the fins, reducing resistance to air flow and reducing energy consumption.

– Extend equipment life: good corrosion resistance helps extend the life of the heat exchanger.

Application areas of hydrophilic aluminum foil for heat exchanger are:

– Air-conditioning system: In the condenser and evaporator of air-conditioning system, hydrophilic aluminum foil can effectively prevent moisture from accumulating, reduce wind resistance and improve heat exchange efficiency.

– Refrigeration equipment: In refrigerators, freezers and other refrigeration equipment, hydrophilic aluminum foil can also improve heat exchange efficiency and extend the service life of the equipment.

– Automotive air conditioning: Hydrophilic aluminum foil are often used for heat exchangers in automotive air conditioning systems to improve cooling effect and energy efficiency.