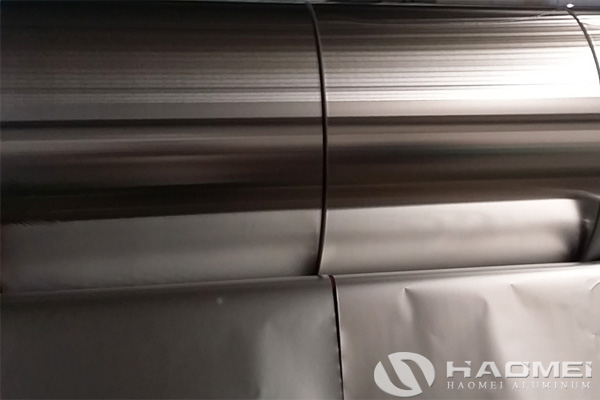

Aluminum foil 1050 and 1060 are the commonly used aluminum grades in air conditioning industry. The air conditioning aluminum foil is a special material for manufacturing heat exchanger fins of air conditioners, and the aluminum foil for air conditioner fins is referred to as air-conditioning aluminum foil. The rapid increase in the output of air conditioners has created a huge market demand for the manufacture of aluminum foil for heat dissipating fins of air conditioners, and has promoted the continuous development of air conditioning aluminum foil product technology. The development of air-conditioning foil technology has been accompanied by the demand for air conditioners.

As a modern product, air conditioners are constantly updated in terms of variety, specifications, models and performance, and fin processing equipment and methods are continuously improved, thereby driving air-conditioning heat exchangers to be miniaturized, thinned, high-performance and structurally optimized. Higher requirements are placed on the mechanical properties, flatness and thickness uniformity of aluminum foil for air conditioner. In order to improve the performance of air-conditioning aluminum foil materials, relevant aluminum processing companies all over the world are conducting technical research, the development of several aluminum grades such as 1060, 1050, 1100 and 8011 aluminum foil, the tempers are O, H18, H22, H24, and H26, the thickness is 0.0045mm-0.2mm, the width is 3mm – 1800mm.