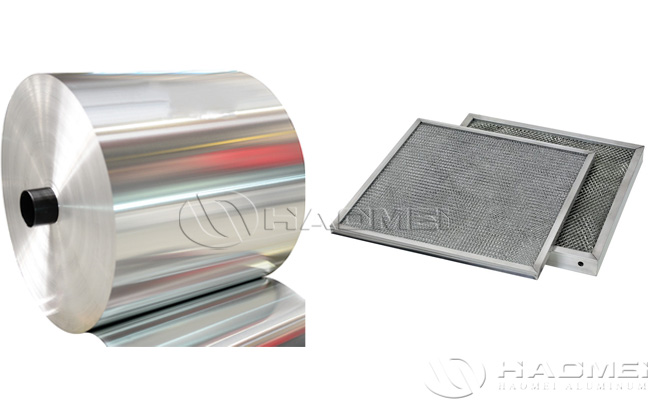

Aluminum foil for air filters produce by Haomei Aluminum is mainly 1070 or 1145 aluminium foil with H17 temper, the thickness is 0.03-0.05mm. In practice, aluminium foil is often made into specific shapes and structures to suit the needs of air filters. For example, it can be used as a support layer or frame for filter materials, providing a stable structure and filtration effect. At the same time, aluminium foil’s ease of processing allows it to be adapted to different shapes and sizes required for the manufacture of air filters. As a result, it is widely used in the manufacture of various types of air filters, such as automotive air filters, household air filters and industrial air filters.

The use of 1070/1145 aluminum foil for air filters is mainly due to its unique physical and chemical properties. The use of aluminium foils in automotive air filters is due to a number of excellent properties that make aluminium foils ideal for use in the manufacture of automotive air filters.

First of all, 1145/1070 aluminium foil has excellent filtration properties. Its special microporous structure enables it to effectively capture and adsorb tiny particles, dust and other impurities in the air, thus improving the filtration effect of the air filter and ensuring that the air entering the car is clean and healthy. This is essential to safeguard the respiratory health of vehicle occupants.

Secondly, 1070/1145 aluminium foil also has good corrosion and oxidation resistance. In the working environment of air filters, the operating environment of automobiles is complicated and changeable, including high temperature, high humidity, dusty and other harsh conditions, and aluminium foil needs to face the erosion and oxidation of various chemical substances for a long time. Due to its specific alloy composition, 1070/1145 aluminium foil has corrosion and oxidation resistance that can resist the erosion of the filter by these environmental factors, maintain the stability of its filtration performance, and prolong the service life of the filter.

In addition, 1070/1145 aluminium foil has high mechanical strength and good processing performance. In air filters, aluminium foil needs to withstand a certain amount of airflow pressure and vibration, and the strength of 1070/1145 aluminium foil is sufficient to meet these challenges, ensuring the stability and durability of the filter. At the same time, the easy processing of aluminium foil makes the manufacturing process more efficient and enables it to meet the large-scale demands of automotive production.

In addition, aluminium foil is a relatively environmentally friendly material that can be recycled, which meets the environmental and sustainability requirements of modern automotive manufacturing.

Finally, the relatively low cost of 1070/1145 aluminium foil makes it suitable for mass production and application. This makes it widely used in the manufacture of air filters in a variety of fields, including automotive, household and industrial.

In summary, with its excellent filtration performance, corrosion and oxidation resistance, mechanical strength and low cost, 1070/1145 aluminum foil for air filters has become an ideal material for air filter manufacturing, which helps to improve the quality of air inside the vehicle and safeguard the health of vehicle occupants.