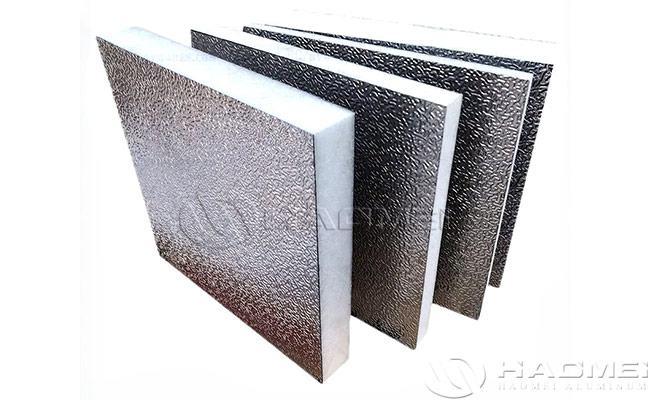

Aluminum foil for composite foam boards is a special surface-treated aluminum foil material that is usually used to enhance the thermal insulation, structural stability and aesthetic appearance of composite foam boards. Aluminum foil has good thermal conductivity and reflectivity, which can effectively reflect heat and reduce heat conduction through the material. The surface texture formed through the embossing process is not only aesthetically pleasing, but also improves the aluminum foil’s resistance to tearing and compression.

Embossed aluminum foil can be laminated with a variety of materials to form thermal insulation foam panels to meet the needs of different fields and application scenarios, the laminating materials including Phenolic Foam, Polyurethane Foam, Rubber Foam, Glass Wool, Rock Wool and other thermal insulation materials. This composite structure combines the heat insulation, moisture-proof and corrosion-proof properties of aluminum foil and the lightweight, high-strength, thermal insulation properties of foam materials, which makes the composite foam boards have a wide range of applications in the fields of construction, packaging, transportation and cold storage.

Aluminum foil insulation foam composite boards are widely used in building insulation, roof insulation, exterior wall insulation, cold storage insulation, pipe insulation, air conditioning pipe insulation and fire isolation. Main Functions:

– Thermal insulation: the reflective properties of embossed aluminum foil can reflect heat and reduce heat conduction, thus improving the thermal insulation effect of the composite foam board, which is suitable for buildings that need temperature control and refrigerated transportation.

– Moisture and anti-corrosion: Aluminum foil has good moisture resistance, which can effectively prevent moisture penetration and protect the foam material from humid environment. At the same time, the anticorrosive properties of aluminum foil can extend the service life of the composite material.

– Enhancement of structural strength: embossed aluminum foil can improve the overall strength and compression resistance of the composite foam board and increase the stability of the material through its texture design.

– Adhesion: The embossed surface can increase the adhesion with other materials (e.g. foam layers or adhesives), ensuring a strong bond between the layers of the composite foam board and avoiding peeling or delamination.

The application of embossed aluminum foil in thermal insulation composite foam board not only improves the functionality of the material, but also enhances the aesthetics and market competitiveness. With the increasing demand for energy saving and environmental protection, embossed aluminum foil has a broad application prospect and will continue to play an important role, especially in the construction and thermal insulation industries.