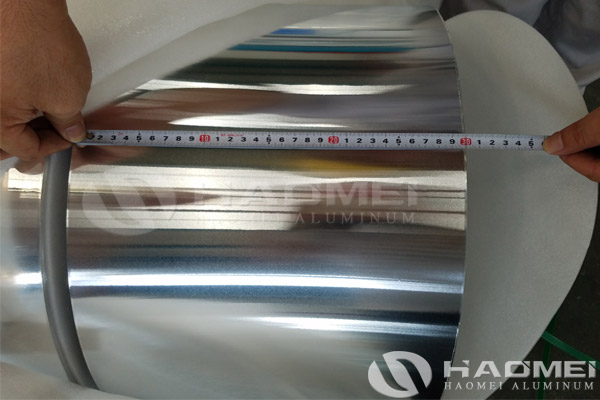

The heavy duty aluminium foil is also called as heavy gauge aluminium foil and thick aluminium foil, it stands for the aluminium foil product with the thickness of 0.1-0.2mm. Due to the heavy thickness, the heavy duty aluminium foil are mainly used for industrial use, which have high requirements on the shield ability and heat conduction. Here are the three common products of the heavy gauge aluminium foil.

1. Air conditioning aluminum foil( aluminium foil for air conditioner)

The Alloy and temper: 3003, 8011-H22/H24/H26

Typical thickness: 0.08~0.2

Processing method: punched into fins

Final use: making heat-conducting fins for air-conditioning heat exchangers.

2. Cable aluminium foil(aluminum foil for cable use)

The Alloy and temper: 8011-O

Typical thickness: 0.1~0.2mm

Processing method: aluminum-plastic composite

Final use: used for coating high-strength cable after aluminum-plastic composite.

3. Container aluminium foil(aluminum foil for food container)

The Alloy and temper: 8011-H24, 3003-H24, 8011-H22

Typical thickness: 0.02~0.20

Processing method: Stamping

Final use: Semi-rigid container for food packaging after punching.

The heavy duty aluminium foil is mainly processed by rough rolling, the rough rolling is similar to the rolling characteristics of the aluminum sheet strip. The thickness control mainly depends on the rolling force and the back tension. The rough rolling processing rate is large can be up to 50%-65%, so the product efficiency is high, and the product quality is great.