Hydrophilic aluminum blue fin are widely used in various heat exchangers, such as automobiles, aviation, ships, refrigeration, air conditioning and other fields. It has significant advantages in reducing energy consumption, improving efficiency, extending equipment life, and reducing maintenance costs, making it an irreplaceable material in the current heat exchanger industry.

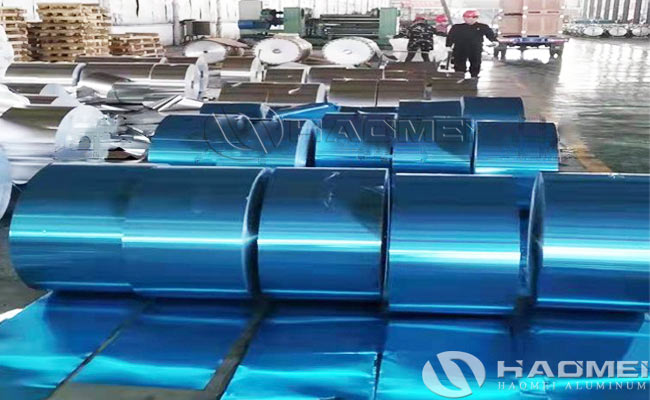

The hydrophilic aluminum foil used for air conditioning heat exchanger fins, also known as “hydrophilic aluminum fins,” is a key material for air conditioning heat exchangers and is equally important as the copper tubes. It affects the overall performance of the heat exchanger. Hydrophilic aluminum foil without any corrosion-resistant coating is silver in color and has no corrosion-resistant coating on the surface. However, currently, many air conditioning fins have corrosion-resistant coatings, often in blue or green, in order to improve the corrosion resistance of the fins. Why is aluminum foil used as the material for air conditioning heat exchanger fins? This is because aluminum foil has the advantages of low density, good thermal conductivity, easy processing, odorlessness, environmental friendliness, and low price.

Hydrophilic aluminum foil is mainly used for air conditioning heat exchanger fins. It has good hydrophilicity, resulting in a smaller contact angle of water droplets on the surface of the fins, allowing them to quickly spread and flow along the surface. Currently, hydrophilic aluminum blue fin accounts for 50% of the total aluminum foil fin stock used in air conditioning, and its usage ratio is expected to further increase. There is also a type of hydrophobic foil fin that gives the fins a water-repellent function, preventing condensation water from clinging. However, further research is needed to improve the defrosting performance of the surface using hydrophobic foil technology.