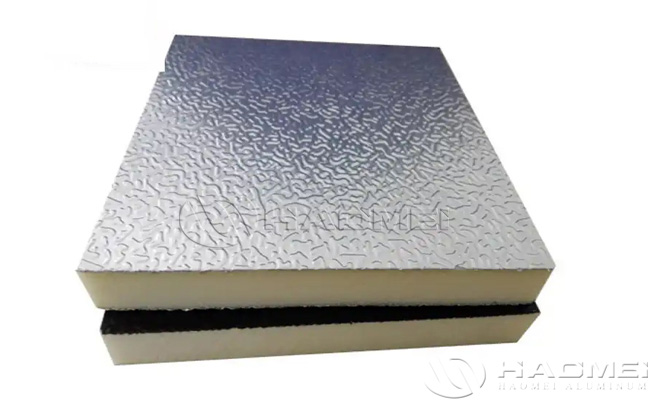

Lacquered aluminium foil embossed for insulation is a high-performance material widely used in construction, industry and transportation. This material not only has a good heat insulation effect, but also has the advantages of aesthetics, light weight, corrosion resistance, etc., so it has a wide range of applications in heat insulation, sound insulation and decoration.

Embossed lacquered aluminum foil for insulation is usually laminated with other materials to enhance its thermal insulation and other properties.

– Substrate: Usually high-quality aluminum foil is used as the substrate, and the thickness is usually between 0.012mm and 0.2mm.

– Surface treatment: It is embossed to form a specific pattern to increase aesthetics and thermal insulation.

Composite materials of lacquered aluminium foil embossed for insulation:

– Foams: such as polyurethane, PUR, PIR, polystyrene (EPS) or extruded polystyrene (XPS). These materials have excellent thermal insulation properties and in combination with aluminum foil can form an efficient insulation layer. The foam provides good thermal resistance, while the aluminum foil further improves insulation by reflecting heat radiation.

– Mineral wool: such as rock wool or glass wool. These materials provide good thermal insulation, absorb sound and offer some fire resistance. When used in combination with insulation aluminum foil, they enhance the overall thermal and acoustic insulation.

– Non-woven fabric: Adding a layer of non-woven fabric to the outer layer of aluminum foil can increase the strength and durability of the material while providing some moisture resistance.

– PVC or PE film: Adding a layer of plastic film between aluminum foil and other insulation materials can increase the moisture-proof performance, prevent water vapor penetration and protect the insulation layer.

Composite method of lacquered aluminium foil embossed for insulation:

– Hot pressing composite: Combine aluminum foil with other insulation materials through high temperature and pressure to form a composite board. This method ensures tight bonding and improves the overall performance.

– Glued composite: Use special adhesive to bond aluminum foil with insulation materials. This method is suitable for applications with high thickness requirements or complex shapes.

– Mechanical fixing: In some cases, aluminum foil can be mechanically fixed to other materials to ensure stability and durability.

- Advantages

– High reflectivity: the surface of embossed aluminum foil is specially treated to effectively reflect thermal radiation and reduce heat transfer.

– Lightweight: Aluminum foil material is lightweight and easy to install and transport.

– Corrosion resistance: aluminum foil has good corrosion resistance and is suitable for use in a wide range of environments.

– Acoustic performance: In addition to heat insulation, embossed aluminum foil also has a certain sound insulation effect.

– Environmental protection: aluminum foil can be recycled, in line with the requirements of sustainable development.

Lacquered aluminium foil embossed for insulation are widely used in light textile, construction, medicine and chemical industry, metallurgy, ships, electrical appliances, cold and heaters, central air-conditioning, mechanical equipment, and other kinds of piping thermal insulation.

In short, by compounding with other materials, lacquered aluminium foil embossed for insulation can achieve better heat insulation performance and wider applications, providing effective solutions for construction and industrial fields.