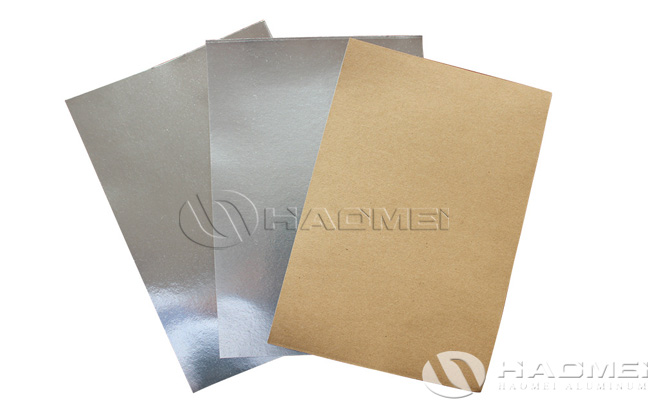

Laminated Aluminum foil with kraft paper is a composite material combining the advantages of both aluminum foil and kraft paper, which is widely used in packaging, insulation, protection and other fields. This composite material has good physical properties and functional characteristics.

laminated aluminum foil with kraft paper

Laminated aluminum foil with kraft paper is usually firmly combined with kraft paper by coating, adhesive or hot melt. The specific production process is adapted to the desired end properties and application. For example, the right type and thickness of adhesive is selected to ensure the stability and durability of the composite. The composite structure usually consists of the following layers:

– Aluminum foil layer:

Function: Provides excellent barrier properties against light, oxygen and moisture, protecting the quality and freshness of the product inside.

Thickness: Typically 6μm to 20μm, depending on application requirements.

– Adhesive layer:

Function: Used to bond the aluminum foil to the kraft paper layer. Usually food grade adhesive is used to ensure safety.

Type: Water-based or solvent-based adhesive, depending on requirements.

– Kraft paper layer:

Function: Provides mechanical strength and protection, enhances the durability of the package and also provides a good printing surface.

Grammage: Usually between 70g/m² and 120g/m² depending on usage requirements.

Features of laminated aluminum foil with kraft paper are:

– Excellent barrier properties: Aluminum foil provides excellent barrier properties to water vapor, oxygen and light, protecting the contents from environmental factors.

– Strength and toughness: the high strength and toughness of the kraft paper itself makes the composite material more resistant to tearing and suitable for packaging that requires a certain mechanical strength.

– Printing suitability: Kraft paper surface is easy to print, can be printed with a variety of patterns, text and logos, to facilitate branding and product information conveyance.

– Environmental friendliness: Compared with pure plastic materials, aluminum foil and kraft paper composites may be easier to recycle or dispose of in some cases, depending on local recycling facilities and technologies.

– Cost-effective: For some specific applications, this composite material can provide better cost-effectiveness while maintaining performance.

Applications of laminated aluminum foil with kraft paper mainly include:

– Food packaging: such as tea, coffee, snacks and other food packaging that requires high barrier properties.

– Pharmaceutical packaging: to protect drugs from light, moisture and oxygen, to ensure the effectiveness and safety of drugs.

– Electronic component packaging: provide electrostatic protection and physical protection for sensitive electronic components.

– Building and industrial thermal insulation materials: Utilizing its thermal insulation properties as a thermal insulation layer for building materials or equipment.

– Logistics and Transportation Packaging: Protecting goods from damage during transportation, especially products that are sensitive to humidity.

This laminated aluminum foil with kraft paper is widely used in food packaging, pharmaceutical packaging, daily necessities packaging and other fields, favored for its excellent protective properties and good mechanical properties.